Inspiring solutions for transformation of mobility

"Inspiring the Transformation:" Under this motto, the DRÄXLMAIER Group will present its innovations from the areas of low voltage, high voltage and battery at the International Supplier Fair (IZB) in Wolfsburg, Germany, Oct. 22-24. With e-mobility and sustainability shaping the vehicle of the future, DRÄXLMAIER will showcase its innovative solutions for these megatrends. The automotive supplier stands for the highest standards and excellent product quality, so that the premium automakers the DRÄXLMAIER Group has supported as a vital partner for decades can continue to lead the market when it comes to the mobility of tomorrow.

“The IZB is the most renowned supplier trade show in Europe,” says Christoph Mahler, head of Key Account Volkswagen Group at DRÄXLMAIER. “We look forward to presenting our expertise and innovations to a very knowledgeable industry audience at this year’s event.”

Low Voltage: Intelligent wiring harness architectures for semi-autonomous driving

The wiring harness system is more than just the sum of data and power lines that run through a vehicle. It represents the bloodstream and nervous system of the automobile. As an pioneer and early innovator in this product area, DRÄXLMAIER is readying the wiring harness system for the future – and this applies not only to the finished product but also to its complex production. By unbundling the wiring harness, the level of automation, efficiency and quality in the production of main harness systems can be continuously increased.

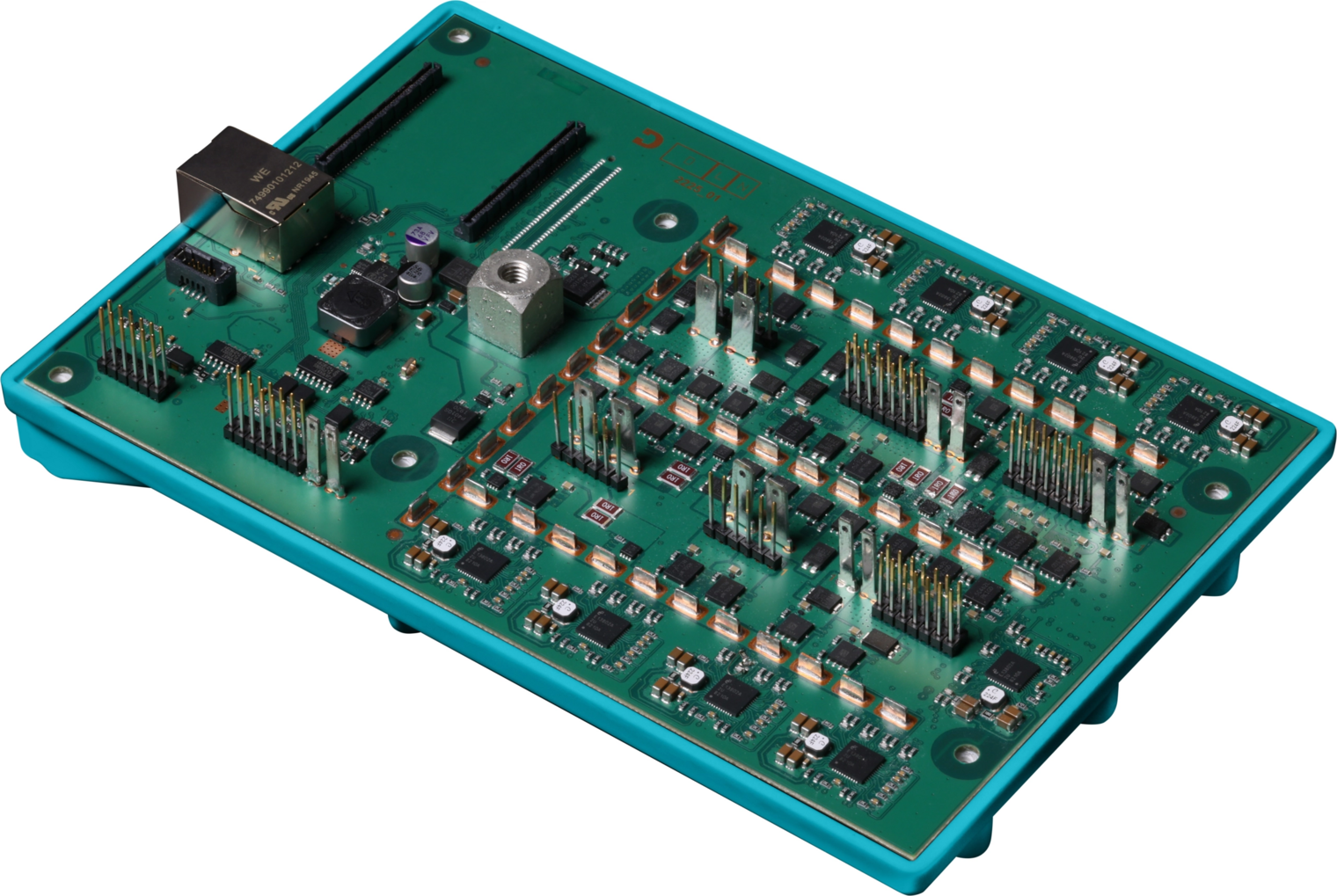

As a system partner, DRÄXLMAIER supports automakers right from the development phase. Whether it is 12 volts or 48 volts, DRÄXLMAIER develops the optimal architecture for every low-voltage electrical system in terms of function and safety. This is especially true for semi-autonomous driving. DRÄXLMAIER relies on a holistic system design approach that intelligently combines conventional and electronic fuses at the various protection levels – to ensure an optimal, trouble-free energy supply and functional safety.

High Voltage: Making charging as easy as refueling

DRÄXLMAIER focuses on the electrification of the automobile as a whole. Be it installation space or temperature management, control electronics or maximum charging current, the supplier optimizes every detail, from the charging socket to the battery cells, for the perfect flow of energy. This ensures that the charging path does not become a bottleneck, ultimately making charging as uncomplicated as refueling. Intelligent architectural designs are crucial in efficient, reliable charging systems – for a perfect interplay between the charging socket, direct current cable, alternating current cable and associated plug systems.

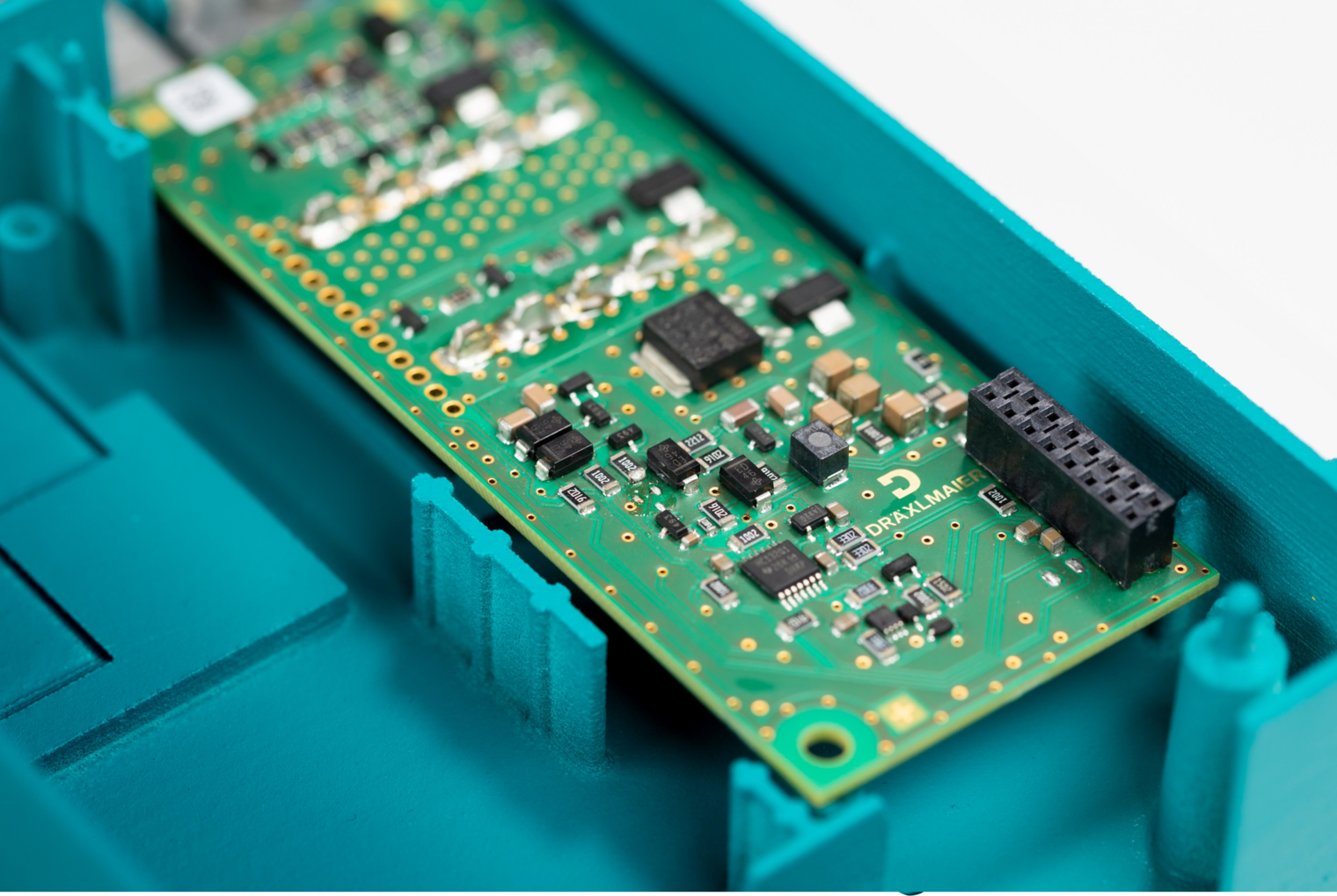

The dFUSE smart HV is a key component for this. This electronic fuse was developed for customer-specific current and voltage requirements in high-voltage electrical systems to increase the reliability of safety-relevant system functions. Faulty high-voltage paths can be switched off within microseconds thanks to the dFUSE smart HV – in both 400-volt and 800-volt electrical systems. The dFUSE smart HV can also be used in the auxiliary unit as well as in the charging path and configured according to the automaker’s requirements. Other functions, such as load monitoring, further increase the benefits of the dFUSE smart HV.

Battery: Efficient system for maximum performance

To develop the full performance of the battery cells, all components of a battery system must optimally work with one another. DRÄXLMAIER has been building expertise in the field of high-voltage battery systems in-house since 2009. Today, as a system provider, the company connects the battery, its control electronics and the charging system to interact with all components efficiently. DRÄXLMAIER has also been producing high-voltage battery modules and battery systems in series for several years and stands for the highest quality, even in large quantities. In addition, the company's own battery test and validation center ensures that battery modules and battery systems are tested and verified from a single source.

“With our expertise in the areas of electrics, electronics, connectivity, charging paths and battery systems, the DRÄXLMAIER Group always focuses on the system as a whole,” stresses Mahler. “This allows us to link a wide variety of areas and create synergies for our customers.”

Everything about the appearance of the DRÄXLMAIER Group at the International Suppliers Fair 2024 can be found at www.draexlmaier.com/izb.

General information

About

DRÄXLMAIER Group

The DRÄXLMAIER Group supplies premium automobile manufacturers worldwide with complex wiring harness systems, central electrical and electronic components, exclusive interiors, and battery systems for electric mobility. The globally present company thereby covers the entire process chain: from the initial idea, through the development process, and up to precisely in-sequence delivery of the products to the assembly lines of automobile manufacturers. As a family business, DRÄXLMAIER also attaches particular importance to responsible and sustainable business practices for the benefit of people, the environment and society.

Founded in Germany in 1958, the company employs over 70,000 employees at more than 60 sites in over 20 countries. In 2023, the DRÄXLMAIER Group generated sales of 5.6 billion euro. Its customers include Audi, BMW, Jaguar, Land Rover, Maserati, Mercedes-Benz, MINI, Porsche and Volkswagen, as well as Californian premium automotive manufacturers.