Performance under extreme conditions

Endurance test benches

At the DRÄXLMAIER validation center, high voltage battery systems are tested under extreme climatic conditions in order to evaluate their aging and performance. Our endurance test benches provide the ideal environment for these demanding tests. By operating the high voltage systems under varying climatic conditions, we ensure that our test parts meet the highest quality standards.

Our testing facilities in detail:

- Climate chamber size: 21 m³

- Test temperature: -48°C to +120°C (max. ±5K/min)

- Relative humidity: Up to 95%

- Electrical operation: Up to 1MW (1200A / 1200V) with temporary overload capability

Corrosion resistance under extreme influences

Salt spray chamber

At the DRÄXLMAIER validation center, high voltage battery systems are tested for corrosion resistance according to standards to ensure that they can withstand the most demanding conditions. Our salt spray chambers provide the perfect environment for these tests, both for indoor and outdoor applications.

Our testing facilities in detail:

- System size: 19 m³ each

- Test temperature: -20°C to +55°C

- Electrical operation: Up to 500KW (1200A / 1200V)

- Test options: Salt spray or condensation climate

Precise leak testing

Dust chamber

The standard-compliant leak test ensures that the test parts function reliably even under extreme conditions. Our dust chamber offers optimum conditions for testing, both for indoor and outdoor applications.

Our test facility in detail:

- Volume: 18 m³

- Electrical specifications: Up to 500kW (1200A / 1200V)

Mechanical stress under extreme conditions

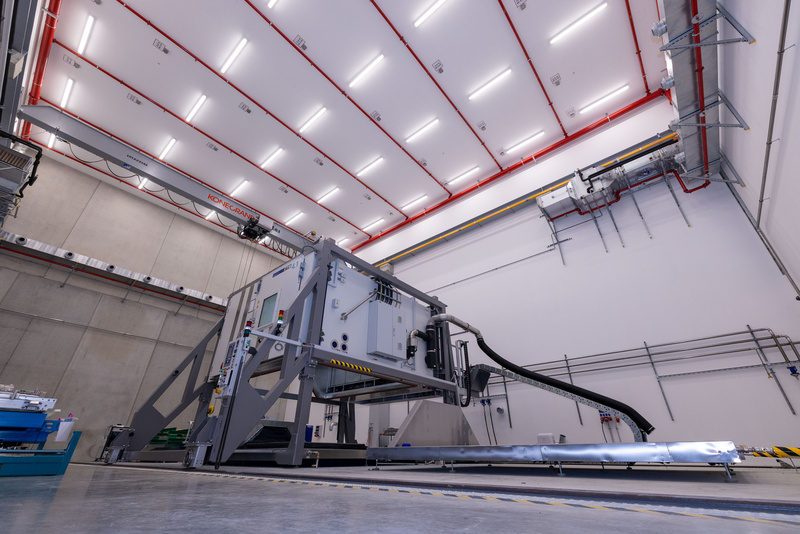

Shaker

At the DRÄXLMAIER validation center, the vibration test system, also known as the “shaker”, is used to test mechanical loads on products. These tests include both vibrations and mechanical shocks, such as those that occur when simulating a kerb crossing or potholes.

Our testing facilities in detail:

- Clamping area: Horizontal 1.50 m x 2.00 m; Vertical 2.00 m x 2.00 m

- Climatic chamber size: 27 m³

- Test temperature: -48°C to +85°C (up to 120°C)

- Relative humidity: Up to 95%

- Electrical operation: Up to 500kW (1200A / 1200V)

- Nominal force: Sine 300 kN / random 270 kN / shock 900 kN

- Frequency range: 5 Hz - 2,000 Hz

- Maximum payload: 5 tons

- Maximum displacement: sine 63.5 mm / random 63.5 mm / shock 76.2 mm

- Maximum speed: sine 2.0 m/s / random 2.0 m/s / shock 3.5 m/s

- Maximum acceleration: sine 70 g / random 70 g / shock 250 g

Ensuring electromagnetic compatibility

EMC hall

In the EMC hall, components and systems are tested for interference emission and immunity to ensure that they comply with the applicable normative and regulatory limits. These tests are crucial to ensure that electronics and systems do not interfere with other devices and are not disturbed themselves.

Our test facility in detail:

- Design: All current EMC standards (measuring range from DC to max. 40 GHz)

- RF amplifier power: Up to 1.5 kW

- Automation: Highly automated EMC measurements

- Integration: Ready for HV batteries and, if necessary, the entire vehicle

- Measuring distances: Up to 5 m (SAC5)

Our strengths

Comprehensive system expertise and know-how

With our in-depth expertise, we guarantee the highest quality and reliability. This also ensures targeted analyses and findings.

Flexibility and fast response time

The best results are always achieved through fast and flexible reactions.

Efficiency through reduction of interfaces

By minimizing interfaces, we optimize efficiency and reduce potential sources of error.